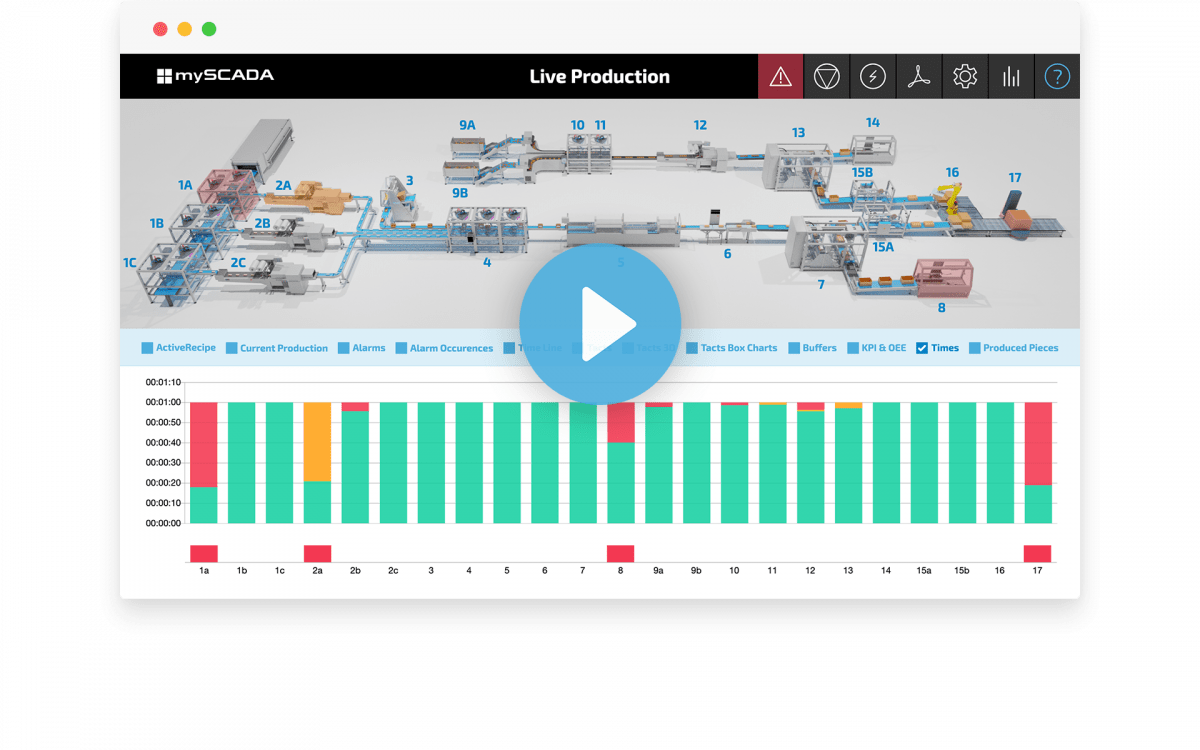

Production overview

Our features:

-

a general overview of the technology

-

timeline tool, collection of all live data, modern widgets

-

KPI and OEE indicators

Your advantages:

Live visualization offers a fast reaction to events immediately as they occur. Live data collection helps production optimization in runtime. Everyone has access to all essential data, including user management (who, when, why, and how something has been changed).

.

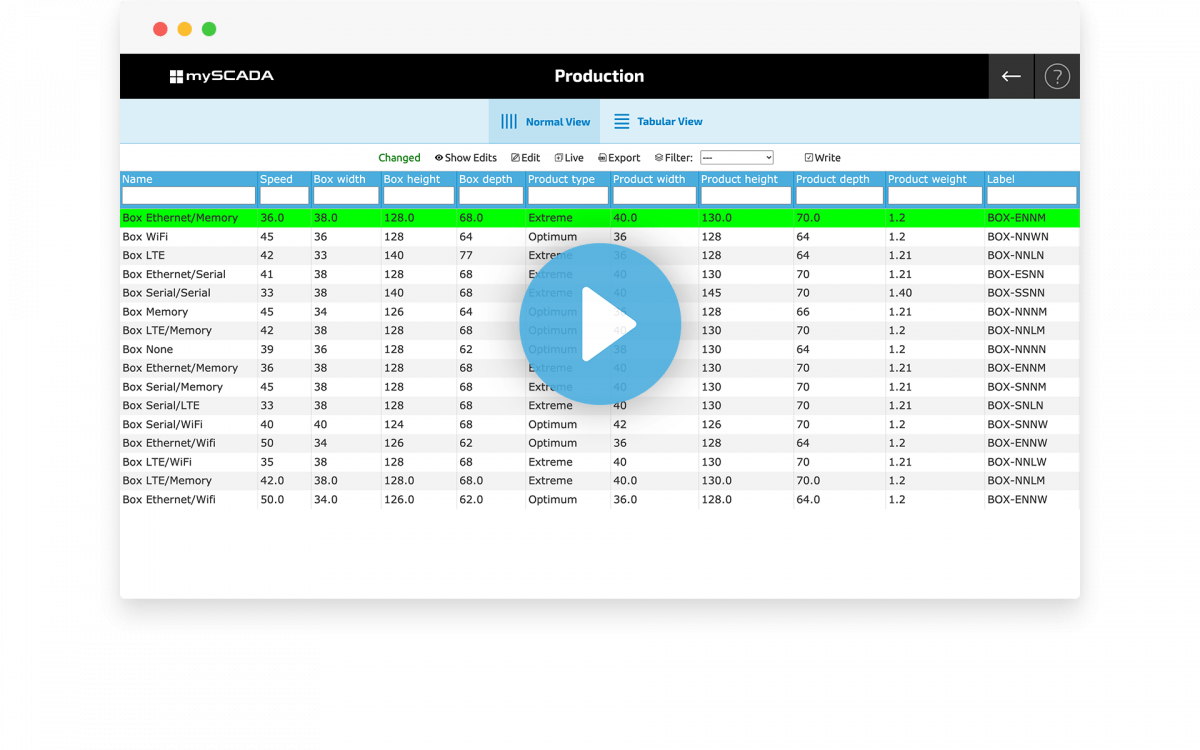

Active control

Our features:

-

active recipe management in runtime

-

clear overview of recipe changes with user management

-

connection with other IT systems like SAP, MES

Your advantages:

Managed control of production parameters ensures stable production, minimal setup time, easy repeatability of orders, and maximal elimination of human errors. With active control, production can be optimized on the fly.

.

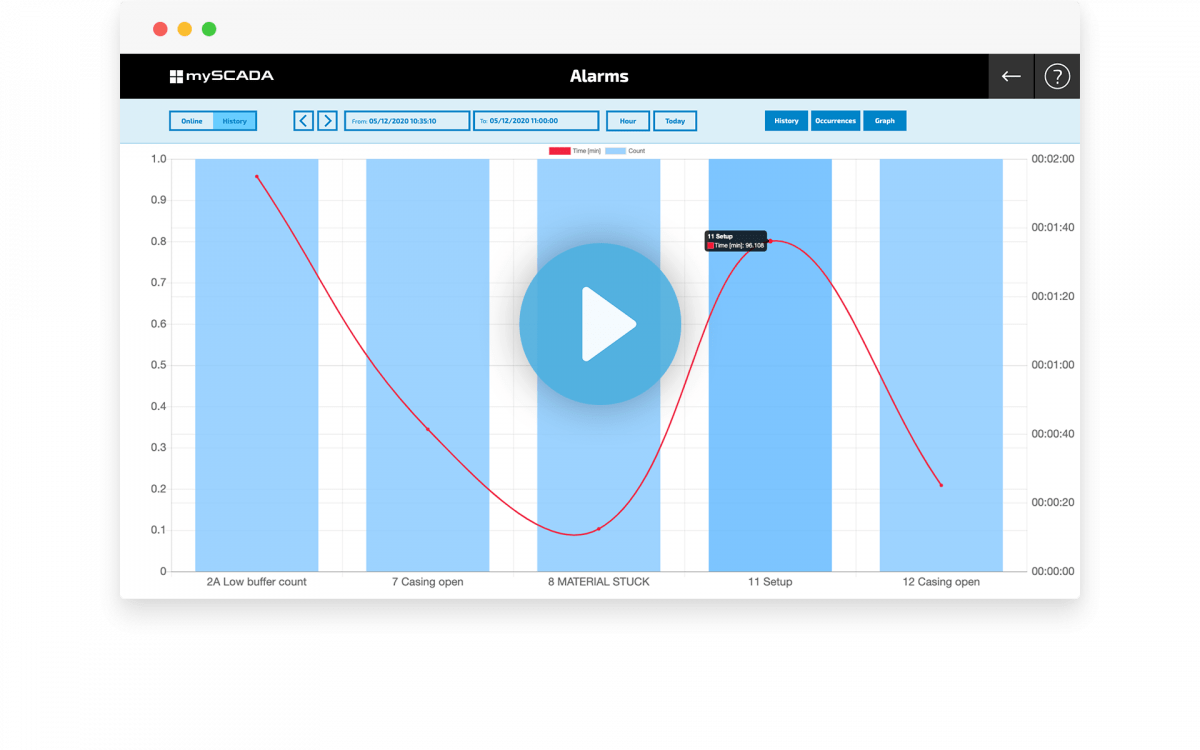

Alarming system

Our features:

-

frequency, occurrence, and time duration statistics

-

notifications to responsible personnel via SMS/email

Your advantages:

The alarm statistics and notifications enable fast elimination of errors just when they occur, decrease downtimes. and help prioritize the error solving process.

.

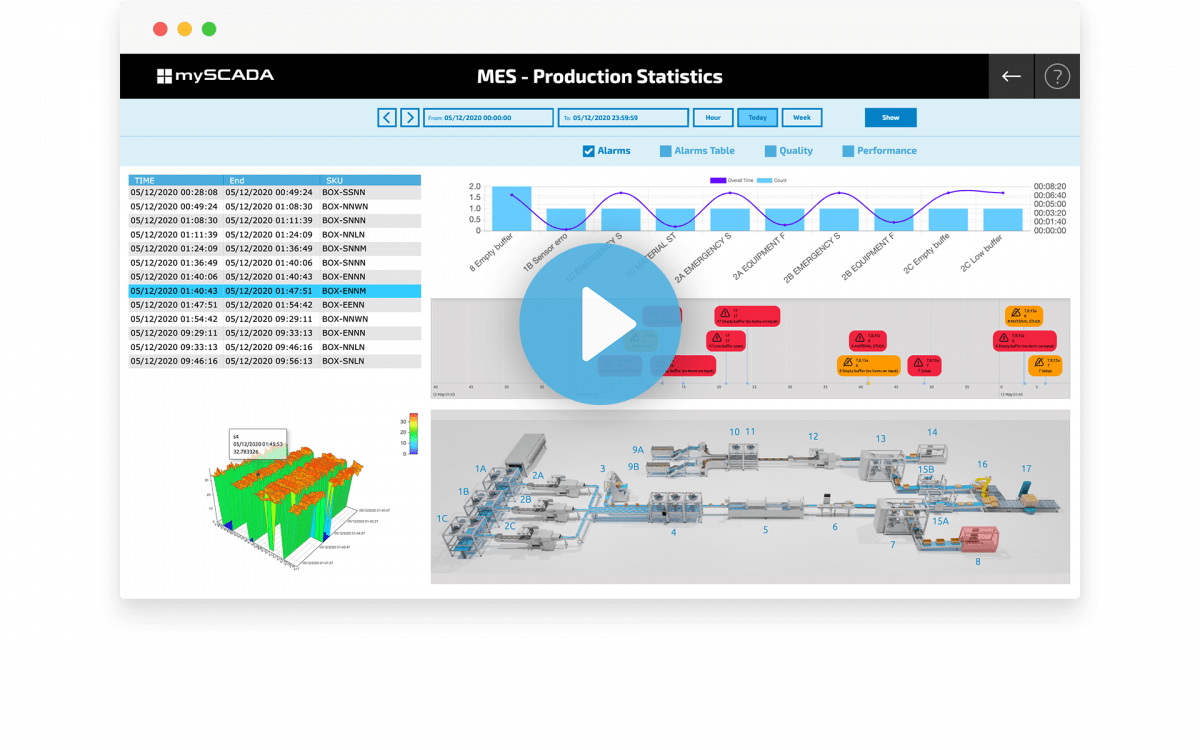

Production statistics

Our features:

-

overview of clear historical data

-

statistics of orders

-

product traceability

-

quality measurement tool

Your advantages:

All statistics about orders, production setup, performance, user actions, etc. help to increase production, eliminate the shortcomings, and optimize all processes. This module is a simple to use, highly customizable MES system.

.

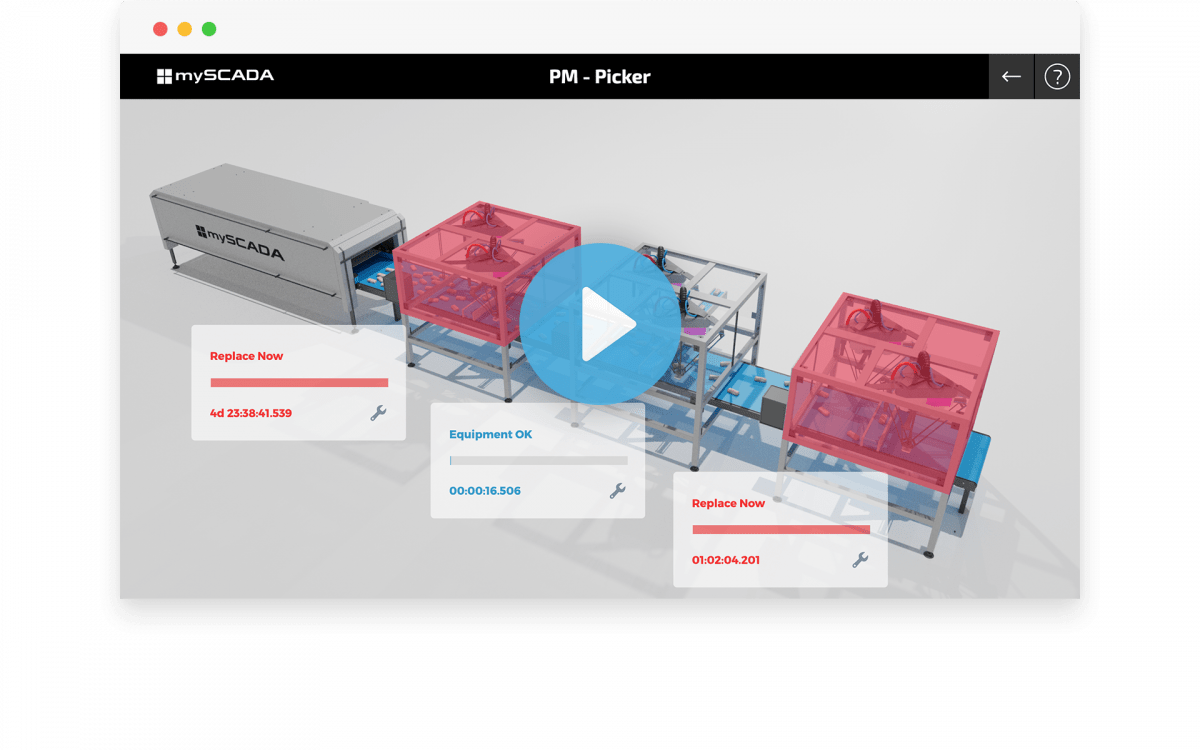

Maintenance and intelligent maintenance

Our features:

-

live forms for regular maintenance

-

intelligent maintenance tool

Your advantages:

Online maintenance materials give a quick overview of all service actions in the factory. In connection with alarm notifications, the repair process is faster and more effective.

Thanks to intelligent maintenance tool, the number of downtimes and unexpected errors is minimized allowing a rapid cost reduction when changing the spare parts (just in time).

.

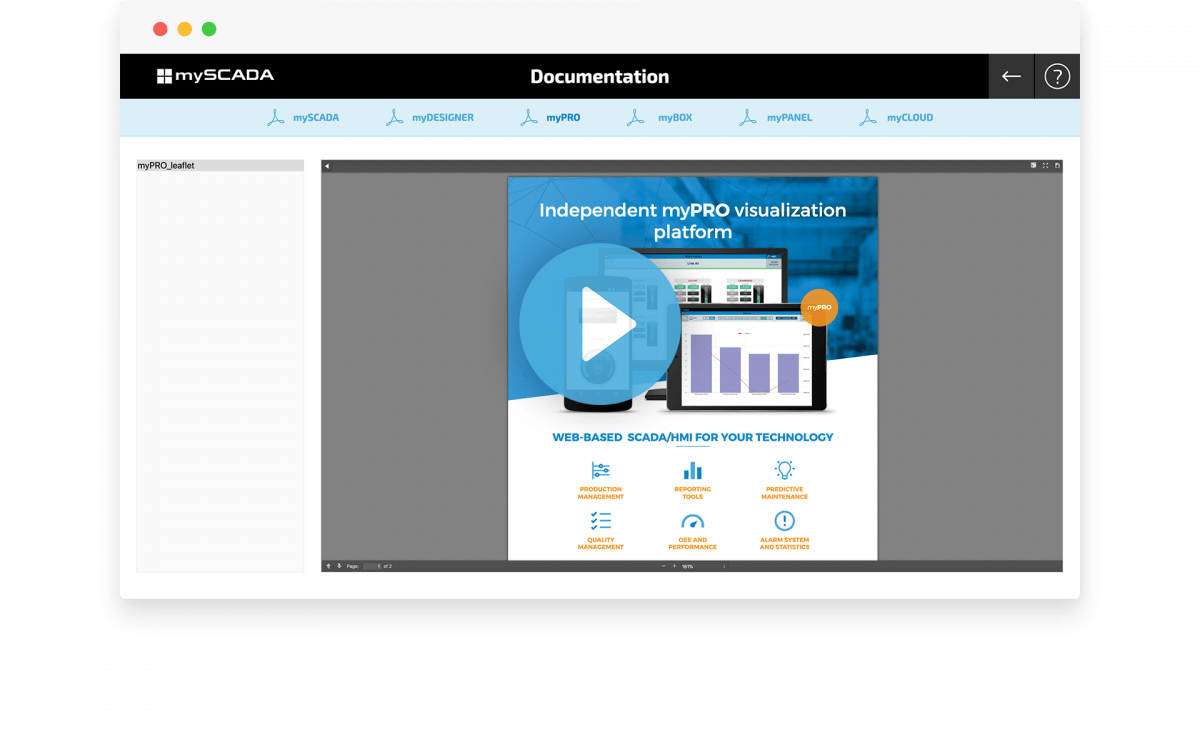

Paperless production

Our features:

-

manuals, diagrams, other documentation available online

-

all changes on the fly

Your advantages:

The paperless factory is an integral part of Industry 4.0 concept. Having paperless production saves not only time (data available in real-time), but it saves operating costs, increases productivity and saves the environment at the same time.

.

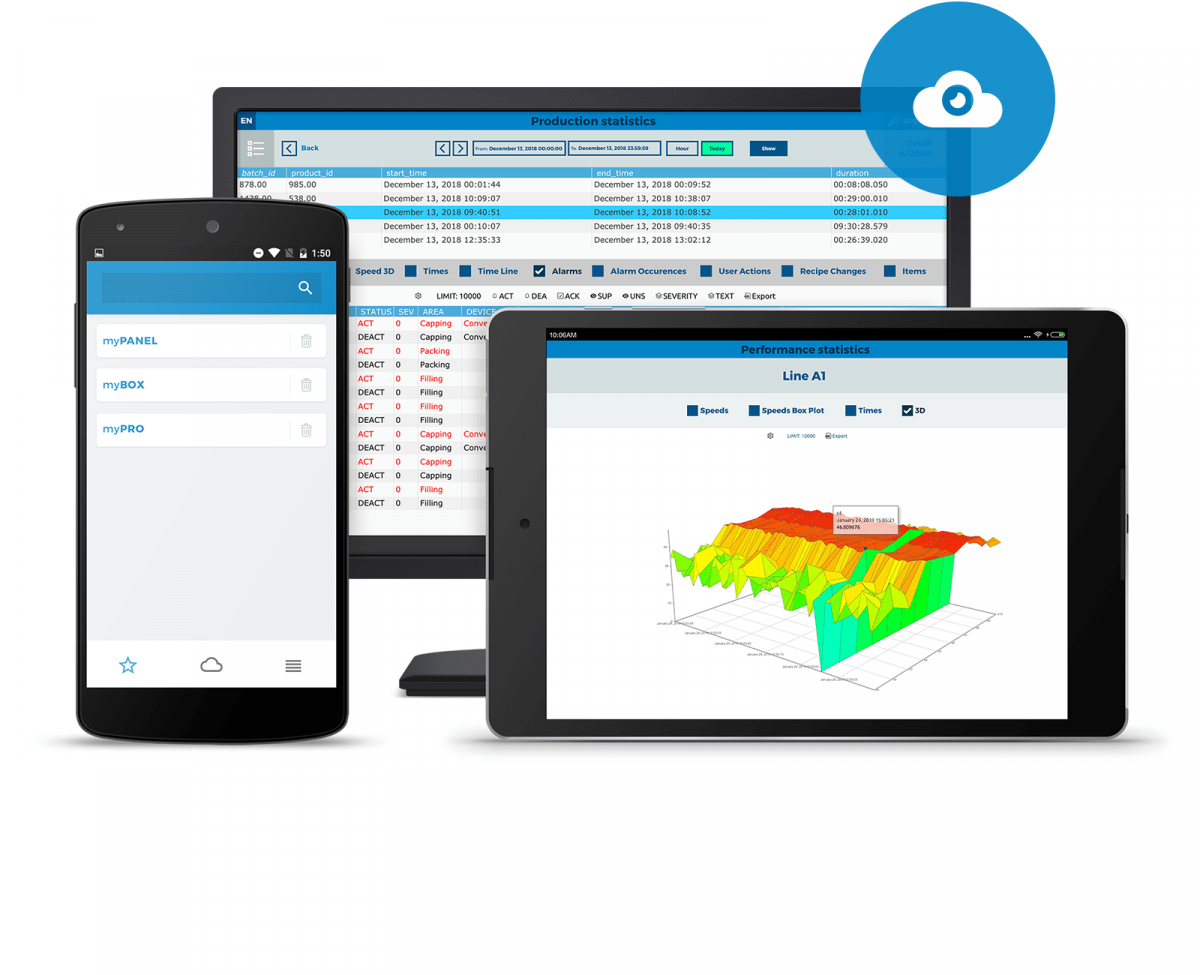

Remote connectivity

Our features:

-

remote access to the technology

-

secure connection between PLCs/SPS and mySCADA

- fast and easy control

Your advantages:

Remote connectivity allows to access not only the technology you need to control but to program the PLCs/SPS remotely while maintaining the highest security level. It brings amazing savings – especially travel costs.

.