Mining Industry

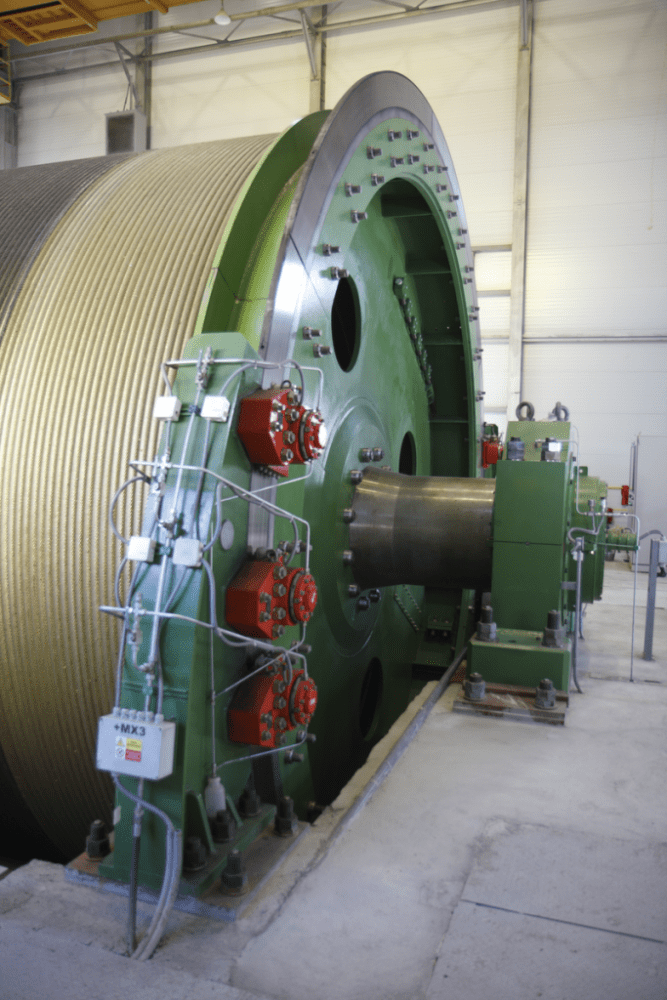

24/7 Remote Diagnostics INCO Engineering s.r.o. is the leading producer of technology for mining hoists and equipment for vertical, inclined and horizontal transport in underground mines and open pit mines. The product portfolio includes hoists with frictional discs, drum hoists, skips, cages and other transport containers, winding pulleys, mine-signaling systems, etc. The company has delivered over 700 hoists as well as a number of other mining products to many countries all over the world.

For its machinery installation in three different locations (Orsk in South Ural, Krasnokamensk, both in Russia, and Ostrava, Czech Republic), INCO engineering developed in cooperation with mySCADA Technologies a system to remotely access INCO machinery on these locations and log its operational parameters.

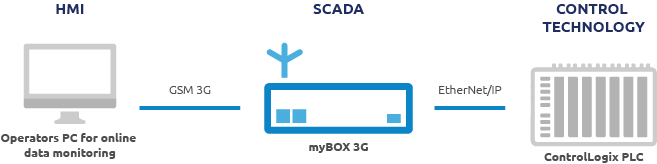

TOPOLOGY

Customer requirements

The major requirement of the customer was to have remote access to the installed mining hoists during the 2-year warranty term. With the remote access, INCO Engineering gained full control and remote diagnosis over its technology. By on-line monitoring and data logging INCO Engineering not only minimized any possible disputes with the customers such as damages caused by overloading the machinery equipment above the maximum certified load capacity, but also provided immediate remote diagnostics to avoid systems failures.

Technical specification and implementation

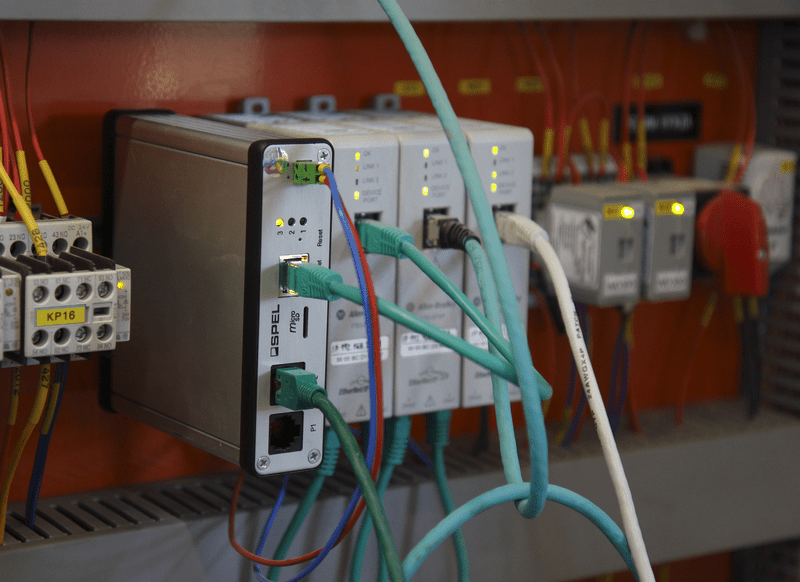

mySCADA boxes with 3G modem were installed and connected to customer’s PLCs from Rockwell Automation controlling the drum hoists. On locations without mobile network, mySCADA Box was connected through local network. INCO Engineering staff was provided with a technical training. The installation on site was supported by mySCADA technicians. All upcoming questions were discussed with mySCADA Technologies technical department and solved within reasonable time to set the equipment into operation.

RESULT

INCO engineering got all the advantages of remote maintenance over 2.500 miles 24/7 through a secure VPN (IPsec) communication link. The company achieved significant savings on both travel expenses and time as its technicians were able to diagnose the machinery on-line status or review the history of alarms and events with integrated software mySCADA Reports from their office in Czech Republic. With logged series of events, any machinery failure, uncertified operations or prediction of possible failure was easily monitored and analyzed. INCO engineering also remotely readjusted or updated any settings of their PLCs to carry out the final fine tuning of all processes.